Why Pragmata?

Advantages of working with us.

About Us

Leading supplier of high precision fasteners & custom-made components in Metals & Engineering Plastics.

With an experience in the field of mechanical/industrial fasteners and custom made engineering components of the promoters that extends well beyond 30 years, Pragmata Engineering was established in the year 2018.

Pragmata Engineering enjoys a well-deserved patronage from its clients due to the quality of products, cost-effective manufacturing processes and satisfaction of customer needs.

The company is a leading firm in terms of manufacturing and supplying high quality and customized fasteners and customized engineering components made from Metals, Engineering Plastics, Rubber and Carbon / Graphite.

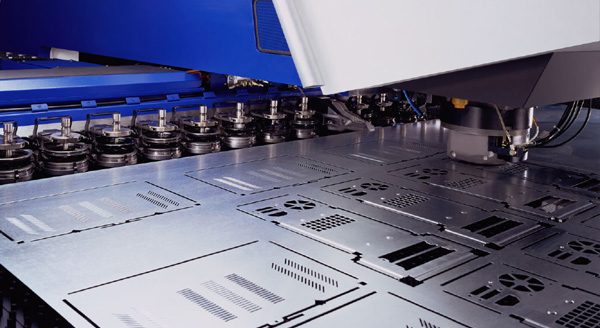

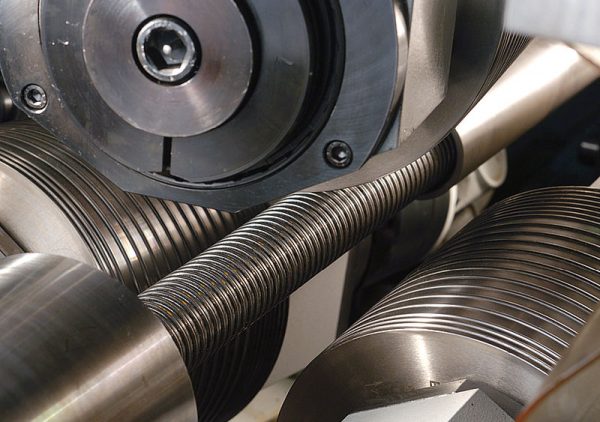

With knowledge and control over primary manufacturing processes such as Hot / Cold Forging, Extrusion, Machining (CNC / VMC), Moulding as well as Casting and all secondary / ancillary processes such as Heat Treatment, Plating / Coating, Welding, Broaching, Milling, Grinding and others, Pragmata enjoys an enviable position as a leading supplier of a wide variety of customized and high precision components.

Our Processes

What processes do we use for manufacturing?